CUSTOMER SERVICE

Smailte Product Appraisal Center

Smailte Product Appraisal Center

In order to eliminate the worries of end customers, Smed has established a product identification center since 2016 to provide customers with "double free" identification services for lamp beads:

① Free shipping: All shipping costs for samples will be borne by Smart;

② Exemption of inspection fee: the whole process of lamp bead inspection service is free, and Smed’s official inspection report will be issued

Contact Person:Mr. Pu

Contact Person:Mr. Pu

Telephone:13823386309

Telephone:13823386309

Mail:pyy@smalite.com

Mail:pyy@smalite.com

Common Problem

What are the precautions for using LED lamp beads?

Before formulating the lamp bead plan, fully understand the specific technical specifications of the whole lamp plan for a single lamp bead (such as: product size and model, photoelectric parameter requirements, and requirements for use under special conditions) and do a good job of docking the plan with business and technical personnel. Work out the most cost-effective light source solution;

Do a good job of various types of sample recognition experiments and small and medium batch trial production verification, comprehensively verify the feasibility of the whole lamp and lamp bead scheme in the actual application process, and do a good job of technical feedback and processing;

For other unexplained matters, it is recommended that customers use lamp beads in accordance with the "LED Lamp Bead Product Regulations".

How does Smalite solve the problem of blackening

The main reason for LED brightness attenuation is the blackening of the silver-plated layer. Blackening can be a vulcanization phenomenon, which refers to the process of chemical reaction between -2 valent sulfur and +1 valent silver to produce black Ag2S due to sulfur (S) in the environment under certain temperature and humidity conditions; also It can be an oxidation phenomenon, which refers to the process in which -2 valent oxygen and +1 valent silver react chemically to produce black Ag2O due to the oxygen (O) element in the environment under certain temperature and humidity conditions; it can also be bromine The phenomenon of bromine (Br) in the environment refers to the process in which -1 valent bromine and +1 valent silver react chemically to produce light black AgBr under certain temperature and humidity conditions. Of course, other 6A and 7A elements may also enter the LED lamp bead package and cause the silver-plated layer to change color and reduce the brightness of the LED lamp bead.

Silicone and silicone resin (herein collectively referred to as silica gel) are commonly used as packaging glue for LED lamp beads. They have a certain degree of moisture and oxygen permeability, especially in high temperature environments, sulfur, oxygen, bromine and other elements are easy to Penetrate the silica gel into the LED lamp bead package.

Smalite Semiconductor Co., Ltd. adopts advanced, cutting-edge and unique PPL technology to solve the blackening problem, depositing a layer of inorganic substance on the surface of the silver plating layer. The inorganic substance has excellent compactness and effectively blocks sulfur, oxygen, bromine, etc. The reaction of the substance with the silver-plated layer. At the same time, it has long-lasting and stable chemical properties, has outstanding performance in corrosion resistance and high temperature resistance, and completely solves the blackening caused by vulcanization, oxidation, and bromination. The vulcanization test of mass-produced products using our company’s PPL technology at a high temperature of 110°C is 40% higher than that of ordinary products.

PPL technology re-endows the long-life characteristics of LED lamp beads. The packaged LED lamp beads can achieve a lifetime (L70) of more than 50,000 hours in most applications. In January 2017, Smed Semiconductor’s PPL The non-vulcanization product solution realized the first mass production in China. The PPL non-vulcanization process solution introduced can cover a full range of SMD, SMC, and EMC products, and can completely solve the vulcanization problem. Up to now, 3 invention patents have been applied for.

Why are red light LED damaged in reflow

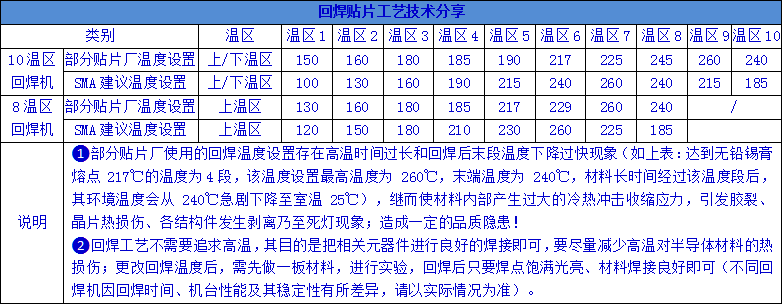

As we all know, most of the small and medium-power red light products currently on the market use single-electrode vertical structure chips. The chip structure is conducive to the diffusion and conduction of heat during the long-term lighting process of the lamp beads, thereby ensuring that the lamp beads have a higher luminous flux. However, the structure of the chip requires an adhesive that can efficiently conduct heat and conduct electricity to fix the chip in parallel with the circuit. Conductive silver glue has become the preferred material commonly used in the industry. This material is composed of a certain proportion of silver powder (particles) and resin glue, and its bonding force will be lower than that of insulating resin glue (because most of the silver glue It is made of silver powder. If the resin glue is added too much, it will affect the conductivity), so it cannot withstand the excessive cold and heat shock stress during the reflow patch process. At the same time, the cured silver glue is easy to get damp, and the red light lamp beads are damp. Later, in the reflow process, "popcorn phenomenon" is likely to occur, and then the red light solid crystal silver glue and the lamp bead bracket will peel off and cause the lamp to die. Therefore, the customer should do a good job of moisture-proof when using the red LED lamp bead. Control. In the actual application process, some customers use the lamp beads by outsourcing, and then neglect the control of the reflow process. During our on-site inspection, we found that some SMD assembly plants that do not understand the characteristics of LEDs often have unreasonable phenomena such as too long high temperature setting time and too high end temperature setting in the reflow process setting, which then causes the internal material to produce Large thermal shock and shrinkage stress can cause glue cracking, thermal damage to the chip, peeling of various structural parts, and even dead lights; causing certain quality risks. To this end, share the following reflow patch process technology for customers' reference:

8-9F, Building 6, Zhongyuntai Technology Industrial Park, Songbai Road,Tangtou, Shiyan, Baoan District, Shenzhen, China, 518108

8-9F, Building 6, Zhongyuntai Technology Industrial Park, Songbai Road,Tangtou, Shiyan, Baoan District, Shenzhen, China, 518108